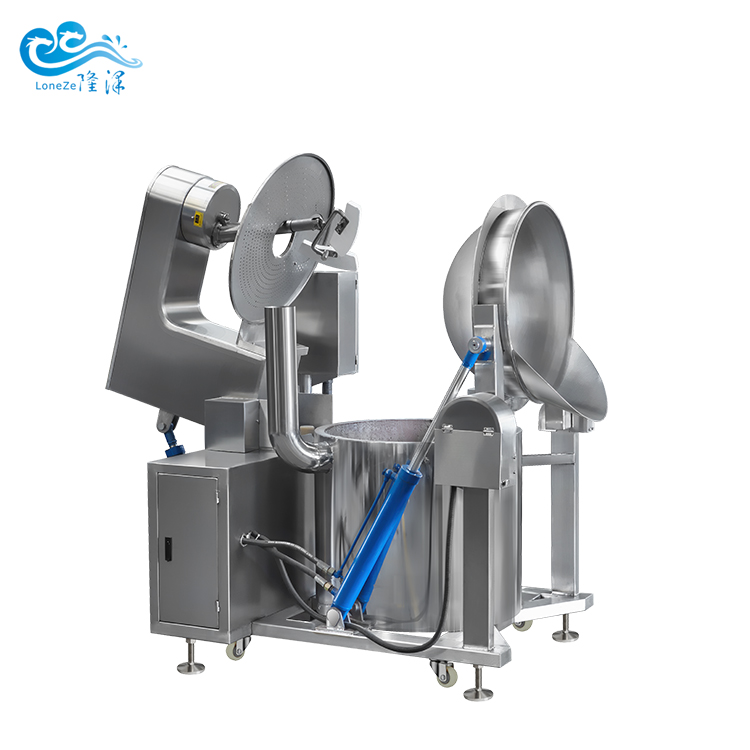

1, horizontal axis stirring wok U-shaped pot body, jacket with gas heating, steam heating, thermal oil heating, electromagnetic heating and other heating methods, variable speed and worm gear, reducer combination of rotation, an increase of horizontal Shaft stirring torque, the use of polytetrafluoroethylene scraper agitator. In the process of material tumbling and stirring, the stirrer and the pot are in full contact with each other in an all-round way to ensure that there is no dead angle for mixing.

2, Horizontal axis stir fry pan open, unloading, reset the motor rotation control, the operation is very convenient. Vacuum frying can also be used to reduce the frying temperature. It is especially suitable for frying of heat-sensitive raw materials, which avoids the bad changes caused by the over-heat caused by the machine, and maintains the original color, smell and taste of raw materials. Improve the efficiency of frying, and reduce energy consumption and shorten the frying time.

Horizontal horizontal

sauce stirring wok characteristics:

1, the horizontal abscissa sauce pan was stirred using an overhead vacuum U-shaped pot, the pot and the surface contact portion 304 are made of stainless steel of high quality, easy to clean, with food hygiene requirements.

2, horizontal horizontal stirring sausage pan trough closed tank, jacket using electromagnetic, electric heating oil, gas, steam heating and other heating methods, heating area, high thermal efficiency, suitable for different materials on the temperature and temperature Speed requirements.

3, no variable speed and worm gear, reducer combination of rotation, increasing the horizontal axis stirring torque. Polytetramethylene material using ethylene blade stirrer, a stirring pan horizontal abscissa characteristics, the mixing process in a tumbling material in full contact with the pan of the stirrer, stirring ensures no dead ends.

4, the lid of the pot, unloading, reset using pressure, mechanical transmission control, the operation is very convenient.

5, the horizontal horizontal axis stir fry pan stir fry pot top vacuum, vacuum frying system can reduce the frying temperature, especially for heat-sensitive raw materials of frying, to avoid overheating caused by the deterioration of color and taste, to maintain The original color, smell and taste of raw materials. Improve the efficiency of frying, and reduce energy consumption and shorten the frying time.

Horizontal horizontal horizontal sauce stirring wok to adapt to:

Suitable for all kinds of stir-fry materials, hot pot at the end of material, spicy sauce and other condiments automatic batter frying processing. Product introduction: The pot at the end of the material wok mushroom sauce wok spicy sauce wok made of stainless steel, horizontal agitation wok application, the pot is 304 stainless steel. plc control, touch screen display and recipe download system. Burner heating energy efficient, horizontal shaft stirring wok maintenance, safe and reliable.

Heating medium heat conducting oil, Ningxia horizontal axis stirring wok, heat evenly heated paste pot. Upside down from the hydraulic station refueling, arm and dumping stable and powerful. 90-degree back-up material can make the pot dumping clean. Dual temperature control system, while testing the material temperature and control the frying temperature.

English

English Español

Español Português

Português Français

Français Italiano

Italiano Deutsch

Deutsch Русский

Русский العربية

العربية हिन्दी

हिन्दी Indonesia

Indonesia ไทย

ไทย Ελληνικά

Ελληνικά Nederlands

Nederlands Türkçe

Türkçe 中文 (简体)

中文 (简体) 日本語

日本語 한국어

한국어