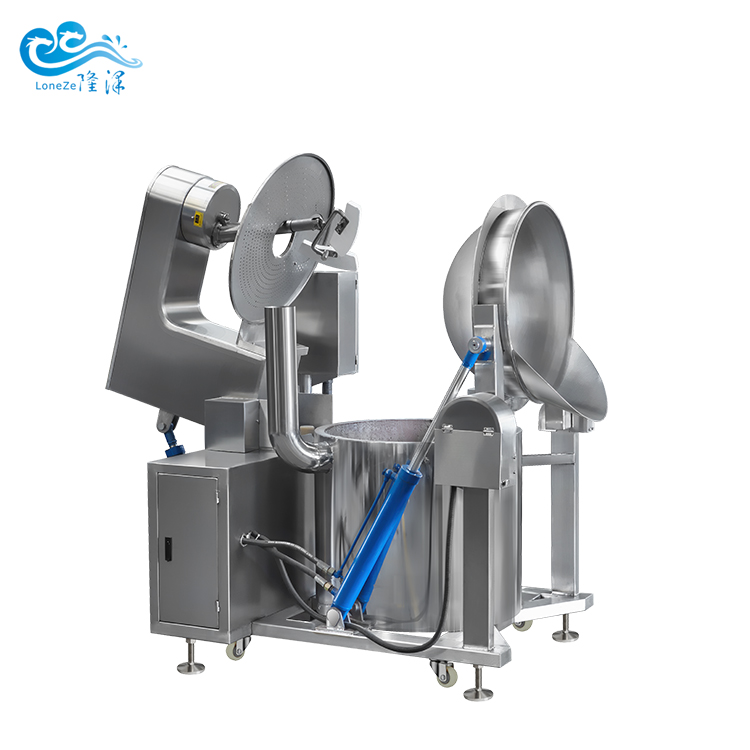

Garlic Chili Sauce Cooking Mixer Pot

2021-03-04 10:37

Shandong Longze Machinery Co., Ltd. directly supplies garlic chili sauce food mixer cooking machine. Buy the garlic chili sauce cooking mixer, choose Longze! Longze garlic chili sauce cooking mixer has been imitated, never surpassed. Planetary stirring cooking mixer, the industry leader, we are professional in chili sauce cooking mixer! Contact: Gussie: +8617560687501 (the same number on whatsapp)

Quick Navigation

Company Profile

Shandong Longze Machinery Co., Ltd. is a scientific research, production, sales service in one of the enterprises. Located in the famous dinosaur town - Zhucheng, the company over the years committed to the development trend of the food industry, the traditional hand-workshop processing reform for the automation, standardization of production. Through automation design and manufacturing for enterprises to save manpower, improve production rate, reduce production costs. Service customers include baking fillings fried industry, meat products cooked food processing industry, condiment industry, candy industry, vegetable corn processing industry, hotel supplies and fast food and other food processing industry, providing heating and cooking frying, vacuum concentration, sterilization Disinfection and other series of equipment.

TO CHEATE EXCELLENT BOUTIQUE

English

English Español

Español Português

Português Français

Français Italiano

Italiano Deutsch

Deutsch Русский

Русский العربية

العربية हिन्दी

हिन्दी Indonesia

Indonesia ไทย

ไทย Ελληνικά

Ελληνικά Nederlands

Nederlands Türkçe

Türkçe 中文 (简体)

中文 (简体) 日本語

日本語 한국어

한국어