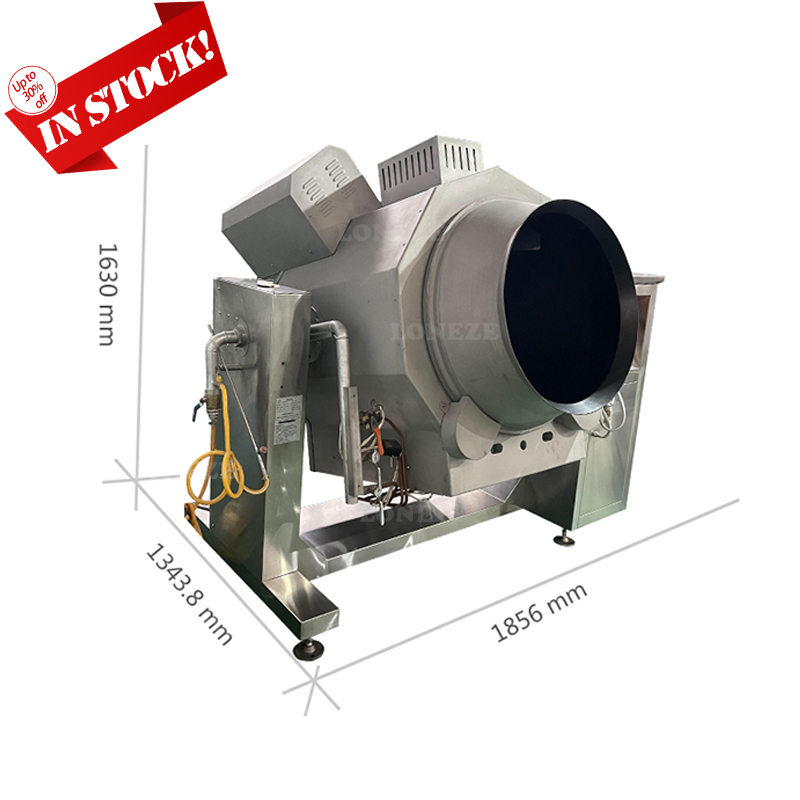

Multi-functional Restaurant Rotary Cooking Drum for Ready Meal

2022-05-28 11:33

Introduction of the stir fry machine

The frying machine is automatic temperature control, free time setting, electronic ignition, adjustable fire power, frequency conversion speed regulation, automatic forward and reverse rotation, electric lift. the main material of the automatic discharge equipment is 304 high-quality stainless steel, the arc pot bottom design, no sanitary dead corners. The frying machine is stable operation, easy operation, high production efficiency and wide application range. Applicable products include: Stir-frying: fried rice, fried noodles, fried rice noodles, fried vegetables, fried pork floss, fried dried meat, fried oats, fried seaweed, fried all kinds of dry goods and nuts...etc. Braised: beef brisket, pork feet, spare ribs, braised pork, chicken, duck, meat sauce,etc.

Features of the cooking drum machine

1.The fire power is adjustable.

2. The equipment turning speed is freely adjusted.

3.The heating time can be adjusted freely according to user needs.

4.Heat evenly.

5.Easy to clean.

Advantages of cooking robot machine

Save your labor costs: From a labor cost perspective, a chef can operate 3 sets of automatic cooking machines, which means that one restaurant can save at least 60% of the chef's cost per year.

Multi-Function Intelligent LED Display: Automatic intelligent cooking robot machine is easy to read the data and operate.

Non-Stick Pot and Integration Base Design: It is safe and durable. And can extend the service life of the auto stir-frying cooking machine.

High-temperature ceramic coating: Thickening coating on the inner wall of the pot, high-temperature resistance, corrosion resistance, there is a stirring bar in the barrel.

High-quality high-pressure spray gun: With 2 Meter hose spray gun make it easy to clean.

Quick Navigation

Company Profile

Shandong Longze Machinery Co., Ltd. is a scientific research, production, sales service in one of the enterprises. Located in the famous dinosaur town - Zhucheng, the company over the years committed to the development trend of the food industry, the traditional hand-workshop processing reform for the automation, standardization of production. Through automation design and manufacturing for enterprises to save manpower, improve production rate, reduce production costs. Service customers include baking fillings fried industry, meat products cooked food processing industry, condiment industry, candy industry, vegetable corn processing industry, hotel supplies and fast food and other food processing industry, providing heating and cooking frying, vacuum concentration, sterilization Disinfection and other series of equipment.

TO CHEATE EXCELLENT BOUTIQUE

English

English Español

Español Português

Português Français

Français Italiano

Italiano Deutsch

Deutsch Русский

Русский العربية

العربية हिन्दी

हिन्दी Indonesia

Indonesia ไทย

ไทย Ελληνικά

Ελληνικά Nederlands

Nederlands Türkçe

Türkçe 中文 (简体)

中文 (简体) 日本語

日本語 한국어

한국어