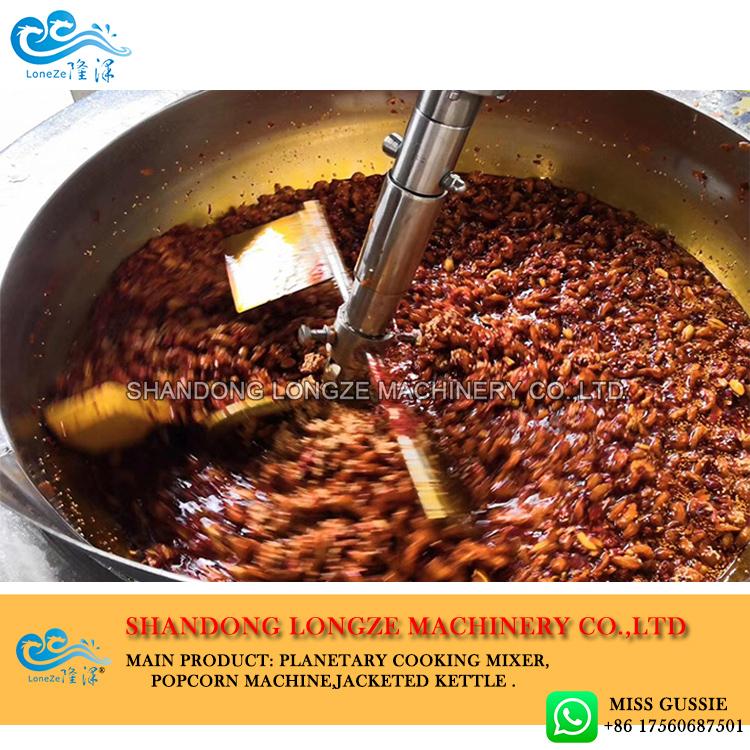

Automatic Sauce Cooking Mixer with PLC Control System

2022-04-30 09:20

Longze automatic sauce cooking mixer burner adopts heat-resistant energy-saving burner. The structure of the whole machine is compact and reasonable, the floor space is small, the standardization of the parts is high, and the maintenance is easy. Compared with similar products, it can save energy by 40%. The burner is annular and surrounds the bottom of the pot. It can be heated by gas and liquefied gas. Can be selected according to the company's existing resources, combined with equipment and technology. The equipment has a high safety factor, and is equipped with phase loss protection and program interlocking functions, which ensures the operation sequence, maintains the equipment, and ensures the safety of operators.

Longze automatic sauce cooking mixer burner adopts heat-resistant energy-saving burner. The structure of the whole machine is compact and reasonable, the floor space is small, the standardization of the parts is high, and the maintenance is easy. Compared with similar products, it can save energy by 40%. The burner is annular and surrounds the bottom of the pot. It can be heated by gas and liquefied gas. Can be selected according to the company's existing resources, combined with equipment and technology. The equipment has a high safety factor, and is equipped with phase loss protection and program interlocking functions, which ensures the operation sequence, maintains the equipment, and ensures the safety of operators.

Features of automatic sauce cooking mixer:

1. High quality: This series of products adopts Beihai head and hemispherical stainless steel pot body formed by one-time stamping.

2. Good applicability: equipment with or without stirring is used according to the needs of the process.

3. Outstanding safety: all parts of this product in contact with food are made of stainless steel and polished, which meets the requirements of the "Food Sanitation Law of the People's Republic of China".

4. High production efficiency: Longze automatic cooking mixer, all the frying work is replaced by machines, through automatic design and manufacturing, it saves manpower for enterprises, improves the yield and reduces production costs.

Features of automatic sauce cooking mixer:

1. High quality: This series of products adopts Beihai head and hemispherical stainless steel pot body formed by one-time stamping.

2. Good applicability: equipment with or without stirring is used according to the needs of the process.

3. Outstanding safety: all parts of this product in contact with food are made of stainless steel and polished, which meets the requirements of the "Food Sanitation Law of the People's Republic of China".

4. High production efficiency: Longze automatic cooking mixer, all the frying work is replaced by machines, through automatic design and manufacturing, it saves manpower for enterprises, improves the yield and reduces production costs.

Quick Navigation

Company Profile

Shandong Longze Machinery Co., Ltd. is a scientific research, production, sales service in one of the enterprises. Located in the famous dinosaur town - Zhucheng, the company over the years committed to the development trend of the food industry, the traditional hand-workshop processing reform for the automation, standardization of production. Through automation design and manufacturing for enterprises to save manpower, improve production rate, reduce production costs. Service customers include baking fillings fried industry, meat products cooked food processing industry, condiment industry, candy industry, vegetable corn processing industry, hotel supplies and fast food and other food processing industry, providing heating and cooking frying, vacuum concentration, sterilization Disinfection and other series of equipment.

TO CHEATE EXCELLENT BOUTIQUE

English

English Español

Español Português

Português Français

Français Italiano

Italiano Deutsch

Deutsch Русский

Русский العربية

العربية हिन्दी

हिन्दी Indonesia

Indonesia ไทย

ไทย Ελληνικά

Ελληνικά Nederlands

Nederlands Türkçe

Türkçe 中文 (简体)

中文 (简体) 日本語

日本語 한국어

한국어